The ISO sets global standards for Conex containers with uniform 20FT (2.13m x 12.2m) and 40FT (2.44m x 12.5m) models, ensuring cross-border compatibility. Internal dimensions, door openings, ceiling height, floor area, and stacking clearance are crucial for usable cargo space. One-Trip Conex containers offer customizable dimensions for diverse storage and transportation needs, with standardized sizes like 20ft (2.438m x 12.192m) and 40ft (2.59m ceiling height) optimizing space usage. Customizing these sizes may incur extra costs. Choosing the right Conex container requires understanding specific dimensional requirements, exterior dimensions (e.g., 8'6" x 8' x 8'6"), and internal measurements for safe handling and efficient logistics operations. Maintaining optimal conditions inside conex containers, including temperature control and protection from elements, preserves their structural integrity and resale value.

“Conex containers, renowned for their versatility in shipping and storage, come in various dimensions, with one-trip options offering unique advantages. This article explores the intricate world of Conex container standards and specifications, delving into the key dimensions of new condition containers. We analyze how size influences storage and transportation efficiency, guiding readers through the process of selecting the ideal unit for their needs. Additionally, we highlight best practices to maintain optimal conditions, ensuring longevity and maximizing resale value.”

- Understanding Conex Container Standards and Specifications

- Key Dimensions of One-Trip Conex Containers in New Condition

- Impact of Size on Storage and Transportation Efficiency

- Choosing the Right Conex Container Based on Dimensional Requirements

- Maintaining Optimal Conditions for Longevity and Resale Value

Understanding Conex Container Standards and Specifications

Understanding Conex Container Standards and Specifications

Conex containers, renowned for their versatility and global recognition, adhere to stringent international standards set by the International Organization for Standardization (ISO). These uniform dimensions ensure compatibility across borders, facilitating seamless transportation and storage solutions worldwide. The ISO 20FT and 40FT conex container dimensions form the backbone of this system, offering standard internal dimensions like 2.13m (width), 2.35m (height), and 12.2m (length) for the 20FT model, and 2.44m (width), 2.67m (height), and 12.5m (length) for the 40FT variant.

These dimensions are not just about overall size; they encompass various critical aspects, including conex container door opening dimensions, ceiling height, floor dimensions, and even clearance for stacking and chassis-ready applications. Factors like these determine the usable cargo space within each container, influencing its intended purpose – whether it’s for general freight, refrigerated goods (conex reefer container dimensions), or specialized equipment transport. Custom conex container dimensions are also available to cater to niche requirements, ensuring that every need finds an appropriate solution.

Key Dimensions of One-Trip Conex Containers in New Condition

One-Trip Conex containers, known for their versatility and durability, offer a range of dimensions to cater to diverse storage and transportation needs. The key dimensions vary based on the specific model and size, but generally include external measurements and internal capacities. For instance, the popular 20ft Conex container boasts an external width of 2.438 meters (8 feet), length of 12.192 meters (40 feet), and a ceiling height of approximately 2.59 meters (8.5 feet). Similarly, the 40ft Conex variant extends these dimensions for increased volume.

Understanding internal dimensions is crucial for optimal cargo utilization. The conex container floor typically offers a flat, sturdy surface with precise measurements, while the door opening dimensions facilitate easy loading and unloading. For specialized applications, various configurations are available, including reefer containers, flat rack containers, open-top containers, and more, each with tailored internal dimensions to accommodate specific types of cargo. These containers’ modular design and customizable dimensions make them a flexible solution for various industries, ensuring efficient utilization of space and effective transportation.

Impact of Size on Storage and Transportation Efficiency

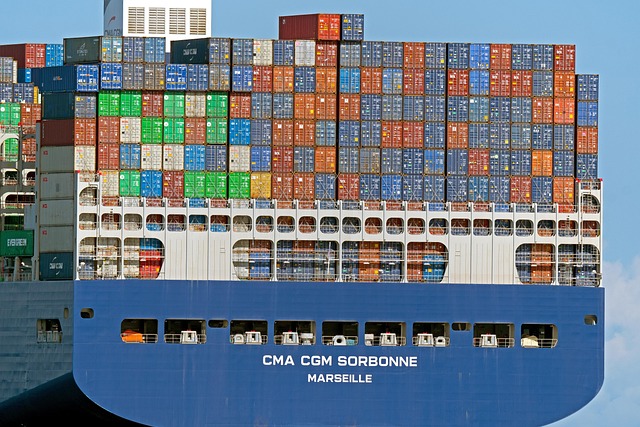

The size of a conex container plays a pivotal role in determining its efficiency for storage and transportation purposes. Standardized dimensions, such as the widely used 20ft and 40ft conex containers, offer optimal space utilization while ensuring compatibility across shipping networks. These universal sizes allow for easy stacking, efficient loading, and seamless transport on trucks, trains, and ships, revolutionizing supply chain logistics.

Understanding the internal dimensions, including floor space, ceiling height, and door opening sizes, is crucial for optimizing cargo configuration. For instance, a 20ft conex high cube container provides ample usable cargo space within its compact dimensions (approximately 3.81m wide, 2.44m high, and 12.19m long), making it ideal for general freight transportation. Similarly, the larger 40ft conex container offers even more storage capacity, with internal dimensions accommodating a wider variety of cargo types and sizes. Customizing these standard dimensions to meet specific requirements, while possible, may introduce additional costs and logistical complexities, emphasizing the value of leveraging existing container sizes for maximum efficiency.

Choosing the Right Conex Container Based on Dimensional Requirements

Choosing the right Conex container involves understanding and aligning with your specific dimensional requirements. These versatile containers come in various sizes, each offering unique advantages for different applications. For instance, a 20ft Conex high cube container is ideal for compact storage or transport of standard-sized goods, while a 40ft unit provides ample space for larger items or bulk cargo. It’s crucial to consider not only the exterior dimensions, like 20ft conex container dimensions (8’6″ x 8′ x 8’6″) or 40ft conex high cube container dimensions (20′ x 8′ x 8’6″), but also internal dimensions, including height, width, length, and floor space. This ensures your cargo fits comfortably, maximising usable cargo space.

Furthermore, factors like door opening dimensions, stacking clearance, chassis readiness, and the container’s overall footprint must be taken into account. Conex containers, with their ISO standards, come in both metric and imperial measurements, catering to global needs. Whether you require a narrow or wide container, a reefer unit for temperature-controlled transport, or a flat rack for specialised cargo, understanding conex container dimension tolerances allows for an exact match to your needs. This ensures efficient use of space, safe handling, and seamless logistics operations.

Maintaining Optimal Conditions for Longevity and Resale Value

Maintaining optimal conditions within your conex containers is crucial for preserving their longevity and resale value. These versatile units are designed to withstand various environments, but proper care can ensure they maintain their structural integrity and internal dimensions over time, especially when considering the diverse range of container sizes available, such as the popular 20ft and 40ft conex containers.

Factors like temperature control, humidity levels, and protection from external elements can impact the overall condition of a conex container. For instance, conex reefer containers require specific refrigeration units to maintain ideal conditions for perishable goods, while flat rack containers necessitate careful consideration of cargo loading and stacking clearances (including door opening dimensions) to prevent damage. Regular cleaning, maintenance, and monitoring of internal dimensions ensure your conex container remains a reliable and valuable asset, whether used for storage, transportation, or as modular offices.

One-trip Conex containers, with their standardized dimensions, offer immense flexibility in storage and transportation. Understanding these dimensions, as discussed in this article, is key to maximizing efficiency. By considering factors like size and condition, users can select the right container for their needs, ensuring optimal space utilization and cost-effectiveness. Regular maintenance practices will further contribute to preserving the containers’ longevity and resale value, making them a reliable choice for various industries.